Can mendakan inpormasi atanapi bahan atanapi produk anu anjeun pikahoyong?

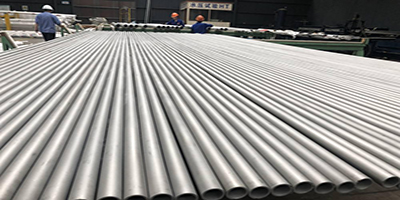

Hoyong Milari Pipa sareng Tube Baja Khusus anjeun?

Grup Logam Seknoic Pabrik sareng Pasokan Rupa-rupa Pipa sareng Tube Aplikasi pikeun Industri, Médis ect, Sapertos Tube Baja Seamless, Pipa Dilas, Pipa Capillary, Penukar Panas, U Bend Tube ect, Tabung Dina Bahan Paduan Titanium, Paduan Berbasis Nikel ( Inconel, Incoloy, Hastelloy, Nimoinc, Ect) sareng Alloy Berbasis Kobalt sareng Pipa Baja Staniless sareng Pipa Sapertos Pipa 304 sareng 316L.

Upami bahan anu anjeun pikahoyong henteu kalebet, mangga ngahubungi kami waé!Kami bakal mendakan solusi.

Nikel Alloy Tube

Nikel Alloy tabung dijieunna tina bahan dumasar nikel kayaning inconel, Hastelloy, Haynes, alloy invar, aranjeunna The-suhu luhur alloy tabung bisa tahan stress tangtu dina suhu luhur 600 nepi ka 1200 ℃ sarta mibanda kamampuhan pikeun nolak oksidasi atawa corrosion.mainly Aplikasi pikeun o lingkungan-suhu luhur jeung industri tahan Korosi.

Titanium Galunggung Tube

tabung alloy titanium anu lampu di beurat, tinggi dina kakuatan sarta unggul dina properties.It mékanis loba dipaké dina alat-alat bursa panas, kayaning exchangers panas tubular, exchanger panas coil, exchangers panas tubular oray, condensers, evaporators jeung jalur transportasi. industri kakuatan ngagunakeun tabung titanium salaku tabung baku pikeun parabot maranéhanana.

Pipa kapiler

Capillary Tube mangrupakeun tabung kalayan diaméter luar leutik kirang ti 10mm, aranjeunna bisa dihasilkeun kalayan bahan tina alloy nikel, kayaning inconel, invar, kovar, sarta alloy titanium sarta steels steels, loba dipaké pikeun precision sirkuit skala optik, sensor industri, alat-alat éléktronik. tabung panyalindungan circuit ect

Pipa Coil (PEX)

| Bahan | Sasmita | Standar | Jenis |

| Baja tahan karat | 304L,TP316/316L | ASTM A312, ASTM A213, A269 A270 | Tube Seamless Tube Weled U-Bend Tube Pipa Coil |

| Nikel Alloy Tube | Inconel 718, Inconel 625, Inconel 600, Hastelloy C276, Hastelloy B, Invar 36, Kovar, Incoloy 800, Incoloy 925 | ASTM B161, ASTM B163, ASTM B165, ASTM 167ASTM B407, ASTM 423, ASTM B444, ASTM B619, ASTM B622, ASTM B626, ASTM B668, ASTM B677, ASTM B690, ASTM B729 | |

| Pipa alloy titanium | Titanium pipa seamless (Gr1 / Gr2) Titanium Weled Pipa | ASTMSB338, ASTMB337, ASTM B861, ASTM B862 |

•••Mitra Pipa sareng Tabung Anjeun•••

| Diaméter luar | Seamless tube: 6.0mm -350mm dilas tube: 6.0mm-620mm Pipa kapiler: 2.0mm-10.0mm Coil tube: 5.0 - 25.4mm |

| OD Toleransi | Numutkeun Klién Sebutkeun Standar |

| Ketebalan / Toleransi | 0.5-3.0mm, coil tube: 0.3-2.0mm, +/-10% |

| Panjang / Toleransi | 5.8meter atanapi 6meter atanapi ngaropéa, ± 0.5mm |

| Métode Prosés | Kode digambar, annealing caang, Jero bead nyoplokkeun |

| Réngsé | Caang annealing |

| Satin / Diamplas / Disikat / Garis Rambut HL: 180 grit, 240 grit, 320 grit | |

| Caang: 400 grit, 600 grit, Eunteung: 800 grit / 8K | |

| Aplikasi | Boiler, Heat exchanger, Condenser, Uperheating tube uap, Pipa cai ngagolak |

| Bungkusan | Unggal Tube dipak ku kantong plastik individuallly lajeng kebat atawa ngaropéa |