tabung kapilér titanium pikeun pamakéan médis

tabung kapilér titanium pikeun pamakéan médis,

CP-Ti, Pipa kapiler titanium murni, Ti-0.20Pd,Ti-3AL-2.5V,Ti-0.15Pd,Ti-0.3Mo-0.8NiTi-0.05Pd, Ti-6AI-4VELI, Pipa Kapilér Titanium,

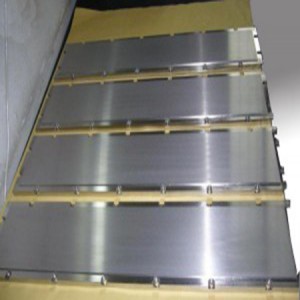

Pipa kapiler titanium:Alatan alloy titanium nu elongation of purity titanium bisa nepi ka 50-60%, sarta ngurangan wewengkon bisa nepi ka 70-80%.Éta ngajadikeun produksi tabung kapilér titanium.Forging jeung rolling nu ingot titanium lebur sekundér kana billet tube, teras manteng billet tube pikeun sababaraha kali nepi ka tube kapilér titanium kabentuk.Alatan kasaluyuan alus jeung awak manusa sarta lalawanan korosi, titanium tube kapilér loba dipaké dina industri médis, kaasup implants awak manusa, alat-alat médis bagian precision internal, jsb.

• Bahan pipah kapilér Titanium: Titanium Murni, Kelas 1, Kelas 2, Kelas 5, Kelas 5, Kelas 7, Kelas 9, Kelas 11, Kelas 12, Kelas 16, Kelas 23 jsb

• Diménsi: OD: 0.2~8mm, WT: 0.015~0.5mm, Panjangna≤6000mm

• Standar:ASTM B338, ASTM B337, ASTM B861, ASTM B862 jsb

| Titanium Alloys Bahan Ngaran umum | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0,20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0,15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Kapilér Tube Komposisi Kimia ♦

| Kelas | Komposisi kimia, persén beurat (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur séjén Max.masing-masing | Unsur séjén Max.total | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0,015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0,015 | 0.40 | 5.5 6.75 | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | 0.12 0.25 | — | 0.12 0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0,015 | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12 0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04 0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦ Titanium capillary tube Pasipatan fisik ♦

| Kelas | sipat fisik | |||||

| Kakuatan regangan Min | kakuatan ngahasilkeun Min (0,2%, offset) | Elongation dina 4D Min (%) | Ngurangan Wewengkon Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦ ♦ ♦ Bahan Paduan Titanium Fitur: ♦ ♦ ♦

•Kelas 1:Titanium murni, kakuatan rélatif lemah sareng ductility tinggi.

• Kelas 2:The titanium murni paling dipaké.Kombinasi pangalusna kakuatan

• Kelas 3:Kakuatan tinggi titanium, dipaké pikeun Matrix-pelat dina cangkang, exchangers panas tube

• Kelas 5:Paling dijieun titanium alloy.Exceedingly kakuatan tinggi na lalawanan panas.

• Kelas 7:Résistansi korosi unggul dina lingkungan réduksi sareng pangoksidasi.

• Kelas 9:kakuatan pisan tinggi na lalawanan korosi.

• Kelas 12:résistansi panas hadé ti titanium murni.dipaké pikeun Kelas 7 jeung Kelas 11.

•Kelas 23:Titanium-6Aluminum-4Vanadium ELI (Tambahan Low Interstitial) Alloy pikeun aplikasi susuk bedah.

Produk kapilér titanium utama nyaéta: tube titanium seamless, tube titanium haliber badag, tube titanium pikeun exchanger panas, jeung sajabana, bisa ngaropéa rupa spésifikasi, manufaktur profésional titanium tube 20 taun kualitas prosés terampil, suplai nyukupan