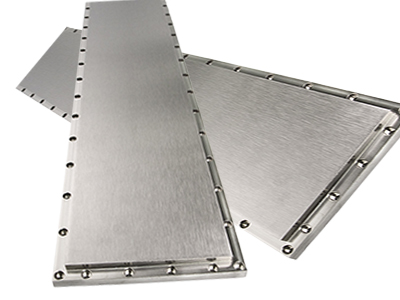

Titanium Lempeng Target

Titanium Target: Urang make titanium alloy billet, atawa plat ka machined kana titanium targets.The eusi impurity of titanium murni industri leuwih ti nu titanium murni kimiawi, jadi kakuatan sarta karasana rada luhur.Sipat mékanis sareng kimiana sami sareng stainless steel.Dibandingkeun sareng alloy titanium, titanium murni gaduh kakuatan anu langkung saé sareng gaduh résistansi oksidasi anu langkung saé.Éta langkung saé tibatan stainless steel austenitic, tapi résistansi panasna kirang.TA1, TA2, TA3 kanaékan eusi najis, kakuatan mékanis jeung karasa ningkat dina urutan, tapi kateguhan palastik nurun dina urutan.

• Titanium Lempeng Target: Kelas1, Kelas 2, Kelas 5, Kelas 5, Kelas7 , Kelas9, Kelas11, Kelas12, Kelas 16, Kelas23 jsb

• Jenis:Sasaran buleud, Sasaran Pipa, Sasaran Lempeng.jsb

• Diménsi:60/80/120(W)×6/8/12(T)×519/525/620(L) &60-800(W)×6-40(T)×600-2000(L)Disaluyukeun

•Surface:permukaan caang atanapi permukaan pickling Asam

• Aplikasi: dipaké dina alat separation semikonduktor, mintonkeun datar-panel, neundeun pilem éléktroda, sputtering palapis, workpiece palapis permukaan, industri palapis kaca, jsb.

| Titanium Alloys Bahan Ngaran umum | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0,20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0,15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Komposisi Kimia ♦

| Kelas | Komposisi kimia, persén beurat (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur séjén Max.masing-masing | Unsur séjén Max.total | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0,015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0,015 | 0.40 | 5.56.75 | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | 0.12 0.25 | — | 0.12 0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0,015 | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12 0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04 0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Titanum AlloySipat Fisik ♦

| Kelas | sipat fisik | |||||

| Kakuatan regangan Min | kakuatan ngahasilkeun Min (0,2%, offset) | Elongation dina 4D Min (%) | Ngurangan Wewengkon Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |