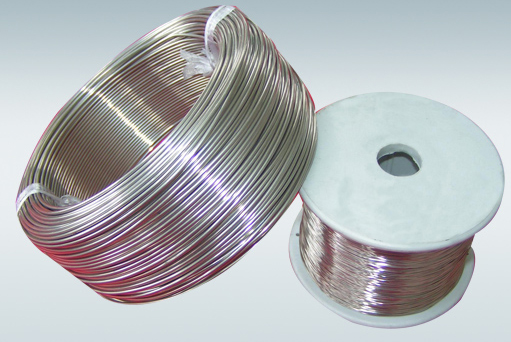

Kawat Titanium

Kawat TitaniumKawat titanium biasana dipaké pikeun las, pigura, implants bedah, hiasan, electroplating nongkrong fixture.Used dina produksi bubuk titanium buleud.

Kawat nganggo titanium bar atanapi titanium slab tinto kapang pikeun ngolah, alatan pangaruh narik, titanium bar deforms dina suhu luhur nalika ngaliwatan liang tina kapang.Bagian melintang diréduksi, sareng panjangna ningkat.Manjang dina kaayaan dipanaskeun ngabantosan ngaleungitkeun setrés internal sareng ningkatkeun palastik kawat titanium.Ieu éféktif ngaronjatkeun precision tina kawat titanium, sarta finish permukaan, nu bisa ngahontal kinerja komprehensif hadé.

• Bahan Kawat Titanium: Kelas1, Kelas 2, Kelas 5, Kelas 5, Kelas7 , Kelas9, Kelas11, Kelas12, Kelas 16, Kelas23 jsb

• Kawat Bentuk: Spool di Coil, Cut panjangna / lempeng

• Diameter: 0.05mm-8.0mm

• Kaayaan:Solusi Annealed, Rolling Panas, Manjang

• Beungeut:Pickling Bodas, Caang digosok, Asam dikumbah, Hideung oksida

• Standar:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 jsb

| Bahan alloy titanium Ngaran umum | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0,20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0,15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Kawat Kimia Komposisi ♦

| Kelas | Komposisi kimia, persén beurat (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur séjén Max.masing-masing | Unsur séjén Max.total | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0,015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0,015 | 0.40 | 5.5-6.75 | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | 0.12 0.25 | — | 0.12 0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0,015 | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12 0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04 0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Kawat Paduan TitanumSipat Fisik ♦

| Kelas | sipat fisik | |||||

| Kakuatan regangan Min | kakuatan ngahasilkeun Min (0,2%, offset) | Elongation dina 4D Min (%) | Ngurangan Wewengkon Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Titanium Alloy Bahan Fitur: ♦♦♦

•Kelas 1: Titanium Murni, kakuatan rélatif lemah sareng ductility tinggi.

•Kelas 2: The titanium murni paling dipaké.Kombinasi pangalusna kakuatan

•Kelas 3: kakuatan High titanium, dipaké pikeun Matrix-pelat dina cangkang jeung tube exchangers panas

•Kelas 5: The alloy titanium paling dijieun.Kakuatan anu luhur pisan.lalawanan panas tinggi.

•Kelas 9: kakuatan pisan tinggi na lalawanan korosi.

•Kelas 12: Résistansi panas anu langkung saé tibatan titanium murni.Aplikasi pikeun Kelas 7 sareng Kelas 11.

•Kelas 23: Titanium-6Aluminum-4Vanadium pikeun aplikasi implan bedah.